It feels like ages since my last write-up of a distillery visit. More than two years! I’ll rectify this horrifying gap by starting small. Really small. In fact, Daftmill distillery might just be the smallest distillery in Scotland, but I’ll get to that in due course. The truth is that when I was planning my trip to southern Scotland last year I got a little…anxious. Not for any characteristic of the Lowlands – they’re perfectly wonderful – but because the area of my trip was woefully devoid of distilleries.

I had already visited Glenkinchie, and besides Bladnoch, which went into bankruptcy just days before my scheduled visit (which was subsequently canceled), there isn’t much besides grain whisky distilleries like Girvan and North British that aren’t accommodating visitors at the moment. When I read about Daftmill distillery, a mysterious, small farm distillery in the center of Fife whose whisky has yet to hit market, I had to visit, and not just to appease that compulsive part of me that wants to visit every distillery in Scotland.

No, not just that. Daftmill is intriguing.

I met Francis Cuthbert, owner and founder of Daftmill distillery, on a rainy, late-April day. Francis is a quiet guy, probably not too much older than me, and part of a family that has owned and farmed this land for six generations. He works full-time farming barley and potatoes and only runs the distillery twice a year when the farm isn’t quite so demanding. Daftmill distillery sits on Pitlair Estate, a pastoral area south of the A91 that runs to Cupar and on to St. Andrews. The distillery is small and beautiful, housed in old farm buildings that date from the early 19th century (though parts go back as far as the 1600s).

Francis kindly agreed to show me around the operation as frigid rain spit down upon us. He and his brother built the distillery in 2003 and began producing whisky in late 2005. Excepting the stills and mash tun, which were built by Forsyths of Rothes, all the work and materials for Daftmill were sourced locally.

Our first stop is the milling room where the barley is ground down for mashing. All of the barley they use for distillation is grown on Francis’s farm. This is good stuff and not the typical Golden Promise and Optic varieties. Francis grows Belgravia, Minstrel, and Publican barley (though the varieties sometimes change), and he has won awards for its quality. The small size of Daftmill’s operation is telling in how the grain is brought to the milling room – in wheeled bins that look a bit like trash cans.

In the brewhouse Francis has arranged the brewing vessels, mash tun, and washbacks with efficiency characteristic of Benromach and Arran. The 1-ton mash tun is a thing of beauty with its copper top and stainless steel semi-lauter rakes trawling through the mash. Four thousand liters of hot water soak the barley and dissolve sugars in the first run followed by another 2,000 liters on the second run. Once the wort is pumped into the washbacks, Francis dumps in the yeast and lets it ferment for an astounding 96-100 hours. That’s an extremely long fermentation, but he’s going for fruity flavors in his whisky and they develop the longer the fermentation runs. He offered me a taste of the beer – the finished product after fermentation – but warned it might give me the “scoots.”

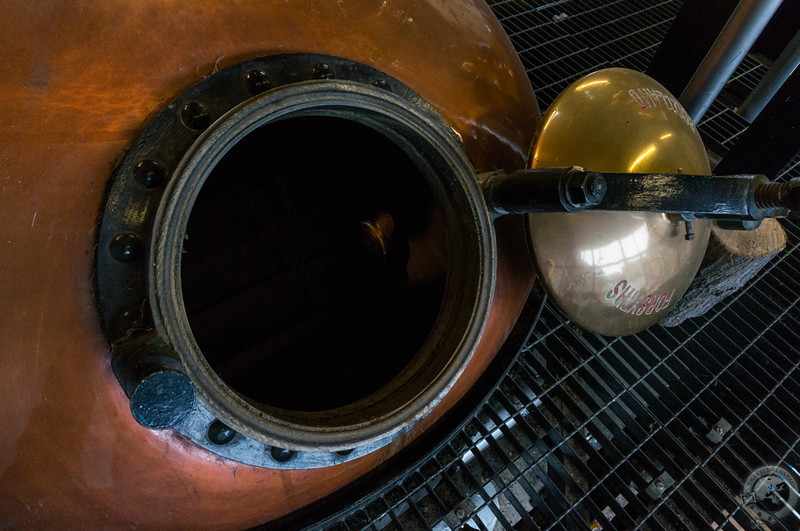

Daftmill’s stillhouse is a converted straw shed, but these days it’s a sight to behold with the two gleaming stills that look brand new despite having run for around eight and a half years (at the time of my visit). Everything here from the shape and size of the stills to the distilling process is designed around the style of whisky Francis wants to produce: A light, lowland whisky with fruity notes. The extra-long fermentation is the first step, but then the small, traditional stills and massive condensers maximize copper contact with the alcohol vapor to remove heavy, sulphury compounds. The stills themselves are quite shallow and they’re filled low so those vapors brush against as much copper as possible on their way up to the lyne arm.

All the production and cooling water comes from Daftmill’s own burn and distillery namesake – the Daft Burn – which earned its name because the water appears to flow uphill. The beginning of each distillation yields spirit clear as water, too, and so the fore-shots or head only runs for five minutes before he turns the knob to direct the flow into the spirit receiver. Most distilleries have a much longer fore-shots run because it is filled with unpleasant aromas and flavors akin to acetone. Perhaps Daftmill’s configuration removes those harmful characteristics. The heart cut here is really potent, beginning around 72-73% ABV – that’s as much as 5% higher than other distilleries I’ve visited.

We leave the warmth of the stillhouse and venture back into the elements on our way to warehouse no. 1. This is a traditional dunnage warehouse with two floors that have yet to be fully filled with barrels. Most of Daftmill’s spirit is sleeping in ex-Bourbon casks from Heaven Hill in Kentucky though Francis does have a couple Sherry butts as well.

There’s a good vibe about the place and I can’t help feeling a bit proud for Francis. He brandishes a dog and begins drawing some whisky out of a cask, dribbles it into a glencairn glass, and hands it to me. It’s cold in the warehouse so I cup it between my hands to open the dram. I’m about to taste whisky that is not on the market yet. Most start-up distilleries get spirit to market ASAP at the three-year mark to begin making money back on their costly venture. Kilchoman, a farm distillery on Islay and Daftmill’s most similar peer, has chosen this route to great acclaim, releasing vintages once or twice a year.

The cask-strength dram from an ex-Bourbon hogshead hits my lips. Fruity, spicy. Lemon zest, black pepper, ginger, and loads of grainy porridge. Some anise. The finish is long and warming almost to the point of spirity, and perhaps this is the detail that prevents Francis from bottling it just yet. The wood needs to knock the strength down a peg.

Another dram fills my glass. This time it’s from a Sherry butt and the color is rich amber. There’s a surprising number of floral notes and the strength of the spirit outshines the cask. The buttery body coats my mouth and esophagus. It’s the perfect way to drive off the chill Scottish spring.

Single malt Scotch whisky is big business. There’s not enough to go around these days as developing markets reveal their insatiable appetites. Demand is changing the game. We see more no-age-statement (NAS) whiskies on the shelves, more mega-distilleries like Roseisle opening, and an increasingly difficult field to navigate with our hard-earned duckets.

Francis has chosen a bold path with Daftmill. It is a low-tech, handmade distillery where most of the year he’s the only employee. He could put out bottles now – years ago even – and whisky collectors and speculators would have bought up the run instantly. Easy. Money in the bank. Not here. He will bottle and sell the whisky when it’s ready. And, by his judgement, it’s not ready yet.

At Daftmill, time is the only master.

Many thanks to Francis for showing me around Daftmill for a couple of hours on a rainy Sunday.

Hooray! I love the distillery posts. Fantastic to have had this opportunity at Daftmill. My concern is that we may never see it in the U.S. due to its limited production. Did Francis share when he thinks he’ll release his first product?

He didn’t make any predictions.

[…] your belly at Daftmill distillery. Daftmill distillery stands on farmland between Cupar and St. Andrews, and here Francis Cuthbert quietly distills small […]

[…] time soon. Every year new distilleries open, further adding to my dastardly workload. Kilchoman and Daftmill are a couple of Scotland’s more recent additions, and Strathearn Distillery, which just […]

[…] that the large-scale distilleries have mostly computerized. Places like Benromach, Kilchoman, Daftmill, and Strathearn all provide insight into the old ways of uisge beatha, but perhaps Edradour, as the […]